The manufacturing industry is certainly no stranger to automation. While production processes on the factory floor have seen astounding advances every decade for the past forty years, back-office processes have tended to lag behind, and many manufacturing companies are still drowning in paper, repetitive manual tasks, and legacy systems.

7 ways manufacturers can automate back-office functions

In this post, we’ll take a look at 7 ways manufacturers can automate back-office functions like HR, Finance, Shipping, and Customer Service to simplify operations, boost productivity, and reduce costs. Let’s jump right in.

1. Human Resources

In spite of the automation boom, manufacturing is still a labor-intensive industry, and that means it’s also an HR-intensive one. So this is one of the first areas manufacturers should consider automating.

There are a lot of online HR software companies out there, but you should look for an all-in-one software with manufacturing clients that understands the unique compliance and regulation issues of the industry. Companies like BirdDog HR offer software that can help automate and standardize tasks like recruitment, on-boarding, training, time and attendance tracking, performance management, and more.

Stuck with some legacy HR processes that still involve paper? You don’t need to rely on manual data entry. With Optical Character Recognition software, you can convert applications, enrollment forms, reports, payroll or any other HR related documents into actionable data without a single keystroke.

2. Finance

Between inventory tracking, component orders, packing slips, purchase orders, and invoicing, the paper trail in the manufacturing industry just for accounts payable and accounts receivable is massive. Even if these documents all come in electronically, sorting them and making sure the data hits the right systems in a timely manner can be a huge time suck.

Setting up some simple automated workflows that can extract data from all of these incoming and outgoing documents to create entries in finance software like QuickBooks can quickly create order out of chaos. An organized finance department means you’ll have much more accurate reporting on things like cash flow, profitability, and forecasting.

3. Research and Development Automation

Whether you’re adding a new product to your line or improving one of your current products, the research and development process involves lots of moving parts… and documents.

In order to get from concept to production, there needs to be a clear line of communication between departments such as engineering and production. This process also involves the creation, management, and sharing of documents such as CAD/CAE drawings, design sheets, standards and specifications, regulatory applications, and more.

Simple task management tools like Trello or MeisterTask can help you keep track of concept versions, production tasks and critical documents making everything visible and searchable by the whole team. Pair them with a document parsing tool, and you can even automatically create necessary tasks from documents like engineering change orders.

4. Compliance

Manufacturers around the world are subject to governmental regulations. Violating these can mean hefty fines, which can be a big financial strain on the company. Effectively managing your compliance information ensures that everyone across the company has access to updated information and adheres to standard operating procedures. This can help improve quality and efficiency. Investing in compliance software such as Donesafe ensures that your entire team has access to up-to-date information.

5. Inventory & Material Management

Finding the perfect balance for production and managing raw materials and inventory is critical for manufacturers. Carry too much inventory, or order too many materials, and you’re dragging down profits. Don’t carry enough, and you can cause a delay in production. With manufacturing software like MiSys, manufacturers can reduce inventory costs, improve production efficiency, and make AI-assisted decisions.

6. Order Processing, Shipping and Delivery

Fulfillment of orders is crucial, and it can get complicated quickly when you’re dealing with a high volume. Manually keeping track of purchase orders, fulfillment, and delivery from various sources takes time and leaves room for error. By automating this process, manufacturers can not only reduce mistakes but also save time and improve efficiency.

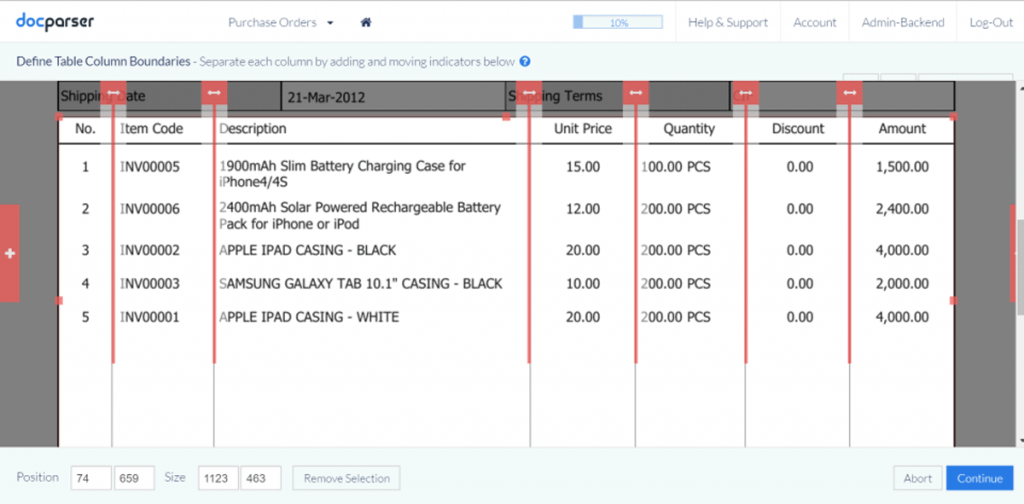

Docparser allows you to fully automate the processing of manufacturing orders with various cloud integrations that make capturing key data from documents (like line items from an invoice) and adding it into your ERP or other in-house systems simple and seamless.

Docparser allows you to fully automate the processing of manufacturing orders with various cloud integrations that make capturing key data from documents (like line items from an invoice) and adding it into your ERP or other in-house systems simple and seamless.

7. Customer Service

Your customer service department is the face of your company, and one of this team’s primary goals and metrics should be based around first-call resolution. This means when customers call, they get all the information and assistance they need in that call.

The challenge? For your reps, this usually involves gathering information from various channels. Having a well-organized Customer Relationship Management (CRM) system such as LiveAgent, and automatically populating customer records with information like order status, shipping date, invoice numbers, etc. means your reps have all of a customers’ information at their fingertips. And that means they can resolve calls quickly while keeping customers happy, which is a win-win for your bottom line, and your business relationships.

From hiring and managing employees to production to customer service, there are end-to-end opportunities to streamline the back-office processes of your manufacturing business. The best part is that in all of these areas, a small up-front investment of time to set up automated workflows can save thousands of hours long term, reduce errors, and give you better insight into your operations.